https://imgchest.com/p/agyvg9qwy89

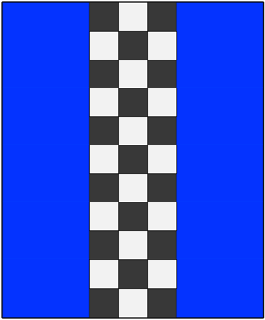

Been having issues with this Inland PETG. I’ve had so many failed prints. This 230C print temp and 80C build temp print was the least f***ed up print I had so far.

I also adjusted combing to Within Infill and retraction to 7mm at 60mms. All other settings should be default on Elegoo Cura N4P Normal settings

Some of the bridging is fine and there are sections that even look good but the rest are covered in blobs and stringing. The inside as it was printing was making noises and small pieces flew out as it was being scraped and stuff. The top layer shows a bit of what I mean.

I’m kind of new to this and can’t seem to narrow down on what the issues are I found online. I’ve adjusted temps and only made it worse. I raised extruder a bit so that helped. I would like to make it looks as perfect as can be like my PLA prints.

Let me know your thoughts below, I’m happy to try them out.

Did you dry it

I reopened a brand new petg filament roll and it had the exact same issues

That doesn’t mean it was dry from the factory I’ve had spools this year from Polymaker that were fine for the first third then had issues symptomatic of wet filament

Try tuning your extrusion multiplier, I’ve found that petg blobs up the nozzle if you don’t slightly underextrude it, running 94% on my filament on the cold side but could probably go down lower, 94% almost completely did away with blobbing issues.

Is extrusion multiplier the same as flow rate?

Edit: changed flow to 94% and that made it worse

It’s something that’s going to be different per filament Ellis’ Guide has a good write up. I found with a 0.6mm nozzle I was getting ridges and stuff in the edges noted that it built up on the nozzle and then deposited blobs throughout the print. Reducing anything that can cause the nozzle to come in contact with material helps too, I use gyroid instead of grid because it doesn’t cross itself for example.

It was absolutely noticeable, I’m using Canadian Filaments - Carbon Capture PETG for reference. I’d also look at drying the filament if possible can help with stringing